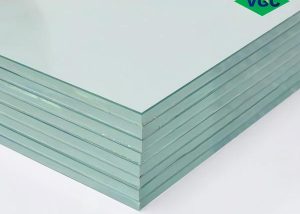

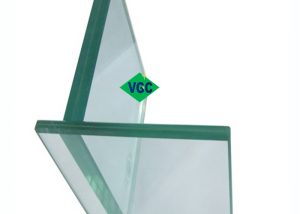

VGC is Clear Laminated Glass Manufacturer and Suppliers from China for more than 15 years. High Safety Laminated glass is produced by laminating one or more layers of organic resin inter-layer between two or more pieces of glass at high temperature and pressure. According to different types of inter-layer, laminated glass can be made into products of different characteristics. Its application should be correctly selected based on the requirements.

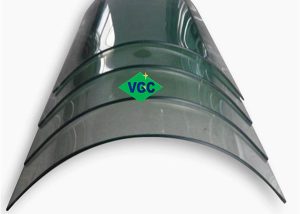

VGC mainly produce PVB /SGP Laminated Glass, Tempered Laminated Glass, Pattern Glass laminated,etc.

VGC Laminated Glass Manufacturer Solutions for Security and Design | Your Trusted Source!

About Safety Laminated Glass (Clear laminated glass manufacturer)

PVB (polyvinyl Butyral) LAMINATED GLASS has full absorption of ultraviolet and good noise-reduction ability. When glass broken, the broken pieces are still attached to the PVB as a whole without falling apart. Thus its protective ability is exceptional and widely used for security.

Safety: damaged due to external force, the glass fragments will not be detached and maintain the integrity. It also avoid being penetrated. It can be processed into bullet-proof glass

or high-strength explosion-proof glass through specific combinations

Sound resistance: PVB has the property of attenuating acoustic wave propagation. Thus, can effectively block sound transmission and reduce noise.

Anti-UV performance: has high UV blockage performance (up to 99% or more), it can prevent the aging & fading of indoor precious furniture, curtains, displays and other items/

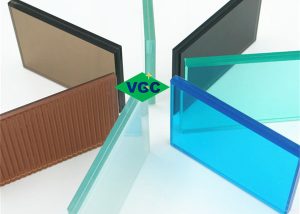

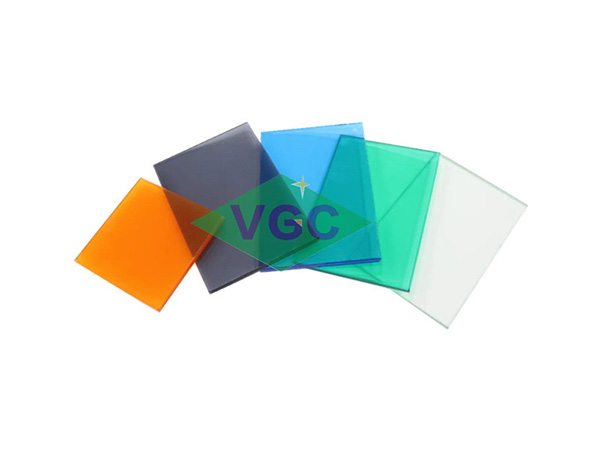

Decorative: PVB has many colors. It gives rich decorative effects when used together with coating and ceramic frit.

Find your partners from China: VGC clear laminated glass manufacturer/

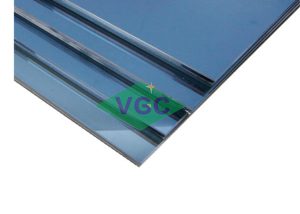

SGP (Sentry Glass Plus) LAMINATED GLASS is an ion-polymer of ethylene and methyl acid ester. It offers more advantages in using SGP as an inter-layer material SGP offers five times the tear strength and 100 times the rigidity of conventional PVB inter-layer Better durability/ long life expectancy s at elevated Temperatures.Excellent weather and edge stability Soundproof Inter-layer glass made by using a special composite PVB inter-layer can achieve better sound resistance. Usually its sound resistance can be improved by 5dB comparing to ordinary PVB with the same thickness.

Specifications

| Product | High Safety Laminated Glass Panels |

| Types | Clear/color/reflective/patterned/Mirror |

| PVB Colors : | Clear;milky white ;bronze;gray;red;orange ;green,etc. |

| PVB Film Thickness | 0.38mm ;0.76mm ; 1.14mm ; 1.52mm ;1.9mm etc |

| Thickness | 2+0 .38PVB+2mm 3+0 .38PVB+3mm 4+0 .38PVB+4mm 5+0 .38PVB+5mm 6+0.76PVB+6mm 8+1 .52PVB+8mm 10+1 .52PVB+10mm etc |

| Normal Sizes | 1830*2440MM,2140*3300MM,2440*3660MM,1650*2250MM,1000*2000MM,1200*1000MM,ETC |

| Processing | Cut to size ;Edge working ;drilling holes ;making notches;tempering.etc. |

| Packing: | Sea worthy plywood end cap ,with film inter layer |

Laminated Glass Vs. Tempered Safety Glass (VGC Clear Laminated Glass Manufacturer)

Applications of High Safety Laminated Glass

High safety laminated glass is engineered with multiple glass layers bonded by polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA) interlayers, ensuring it remains intact (or fragments adhere to the interlayer) upon impact, preventing splintering and penetration. Its exceptional safety, sound insulation, UV resistance, and blast-proof performance make it ideal for diverse B2B scenarios across industries. Below are its key applications:

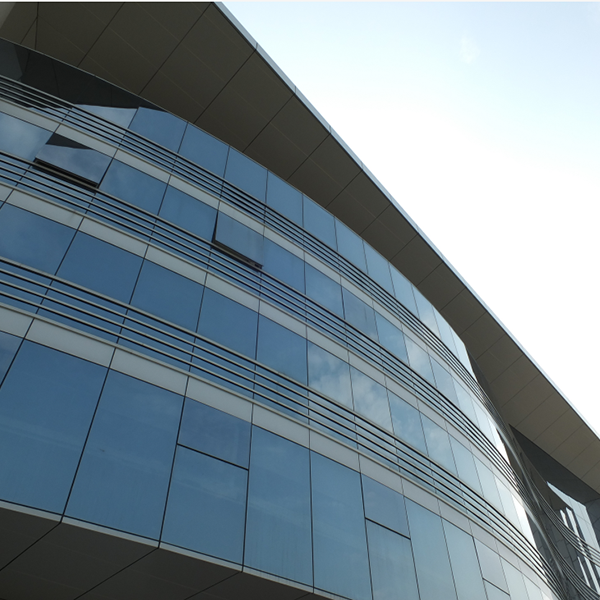

1. Architectural & Construction Industry

- High-rise Building Facades & Curtain Walls: Prevents glass fragments from falling and injuring pedestrians in case of wind pressure, impact, or natural disasters (earthquakes, typhoons).

- Interior Partitions & Balustrades: Used in shopping malls, office buildings, and residential complexes for stair railings, balcony barriers, and elevator enclosures—eliminates safety hazards from broken glass.

- Bank & Jewelry Store Counters/Showcases: Resists smash-and-grab thefts with its anti-penetration property, protecting valuable assets while maintaining visibility.

- Skylights & Canopies: Withstands hail, falling branches, or debris impact; prevents collapse and ensures light transmission for commercial buildings, airports, and railway stations.

- Soundproof Windows for Noise-sensitive Areas: Applied in hotels, hospitals, schools, and recording studios—its interlayer reduces external noise (traffic, construction) by 30–40 dB.

2. Automotive & Transportation Sector

- Automotive Windshields: The core application—remains intact upon collision to protect drivers/passengers from ejection; also blocks 99% of harmful UV rays to preserve car interiors.

- Train & Subway Windows: Resists vandalism, stone impacts, and passenger collisions; ensures cabin safety during high-speed operation.

- Ship & Yacht Windows: Withstands harsh marine conditions (salt spray, wave impact) and prevents water leakage if damaged; meets marine safety certification (e.g., IMO standards).

- Aerospace Cabin Windows (Light Aircraft): Provides impact resistance and pressure stability for small aircraft and helicopters.

3. Specialized Safety & Security Fields

- Blast-proof & Bulletproof Glass Systems: Customized with thickened interlayers and multiple glass plies for military facilities, government buildings, embassies, and cash-in-transit vehicles to resist explosions and ballistic attacks.

- Museum & Exhibition Hall Displays: Protects cultural relics, artworks, and precious exhibits from accidental damage, vandalism, or theft while allowing clear viewing.

- Industrial Factory Partitions: Used in manufacturing plants with heavy machinery, chemical workshops, or welding areas—prevents shrapnel from injuring workers and isolates hazardous areas.

4. Residential & Household Applications

- Shower Enclosures & Bathtub Screens: Eliminates the risk of injury from broken glass in wet, slippery bathroom environments.

- Sunrooms & Greenhouses: Resists extreme weather (hail, heavy snow) and UV radiation, extending the service life of indoor furniture and plants.

- Smart Home Glass Panels: Compatible with film coating technologies (e.g., heat-reflective, self-cleaning) for energy-efficient windows and smart partition walls.

5. Public Infrastructure Projects

- Bus Shelters & Ticket Booths: Withstands vandalism and weather erosion; maintains structural integrity for long-term outdoor use.

- Stadium & Arena Glass Barriers: Protects spectators from flying balls or debris during sports events while ensuring unobstructed views.

- Tunnel & Overpass Sound Barriers: Reduces traffic noise pollution for nearby residential areas and improves driving safety.

High Safety Laminated Glass for Curtain Walls and Glass Stair Cases ( Clear laminated glass manufacturer)

Price from VGC Laminated Glass Manufacturer

| CLEAR LAMINATED GLASS | $6-$12/SQM |

| TINT LAMINATED GLASS | $8-$12/SQM |

| REFLECTIVE LAMINATED GLASS | $9-$12/SQM |

| LAMINATED PATTERN GLASS | $10-$15/SQM |

| LAMINATED MIRROR GLASS | $8-$12/SQM |

FAQs-Clear Laminated Glass Manufacturer VGC

Why Choose Us?

VIRTUE GLASS has always put product quality in the first place as product quality is the life of an enterprise. We try to implement the sense of quality to the heart of every employee,into the production of each link and details, strive for excellence. We take customer’s satisfaction as the main criterion for the assessment of all the production activities, customer demand is always our pursuit.

High Safety Laminated Glass Related Topics

- laminated glass manufacturer China/laminated glass thickness/1 4 laminated safety glass/Toughened Glass Laminated

- Bulletproof laminated glass/Hurricane-resistant laminated glass/UV-filtering laminated glass

- Laminated glass doors/Decorative laminated glass