Clear Float Glass Laminated Glass from VGC China| Get a Free Quote Today~

Looking for high-quality Architectural Clear Float Glass Laminated Glass products for your home or office? Check out the options available at VIRTUE GLASS TECH and find the perfect fit for your needs! VGC is a leading Architectural Glass manufacturer and supplier. Our products are of the highest quality and offer superior safety and security. Architectural Glass is the perfect solution for safety and security. Explore our range of laminated glass products and get a free quote today from Virtue Glass Company. Upgrade your windows and doors with laminated glass from our selection of hurricane, soundproof, and decorative options. Choose the ultimate safety solution for your home or business.

Clear Float Glass Laminated glass is produced by laminating one or more layers of organic resin inter-layer between two or more pieces of glass at high temperature and pressure. According to different types of inter-layer, laminated glass can be made into products of different characteristics. Its application should be correctly selected based on the requirements. VGC mainly produce PVB Laminated Glass, SGP Laminated glass, Tempered Laminated Glass, Tinted Laminated Glass, Pattern Glass laminated.

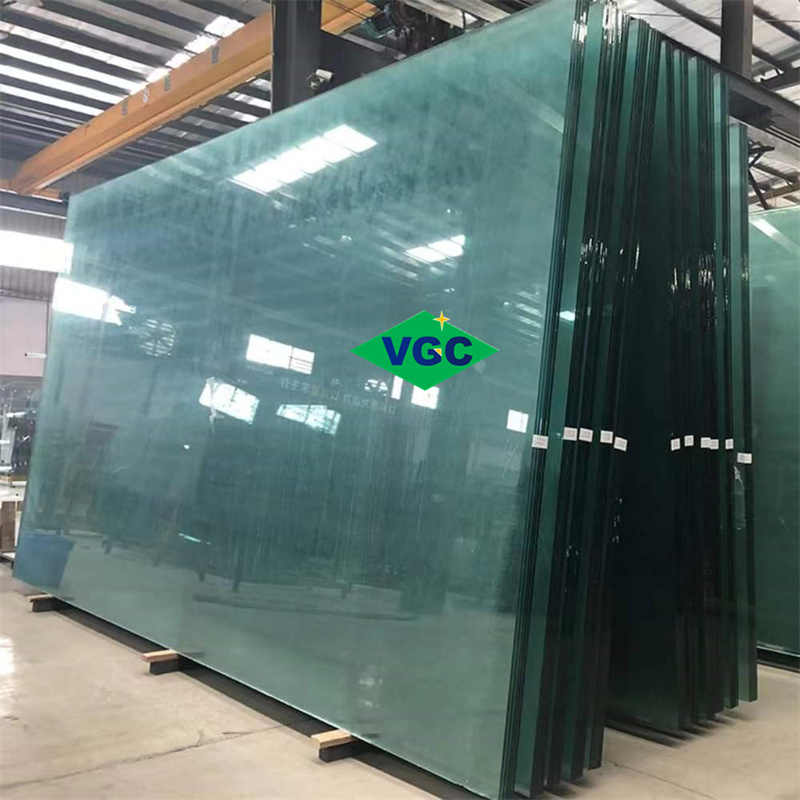

clear float glass laminated glass for sale

Skylight Laminated Glass

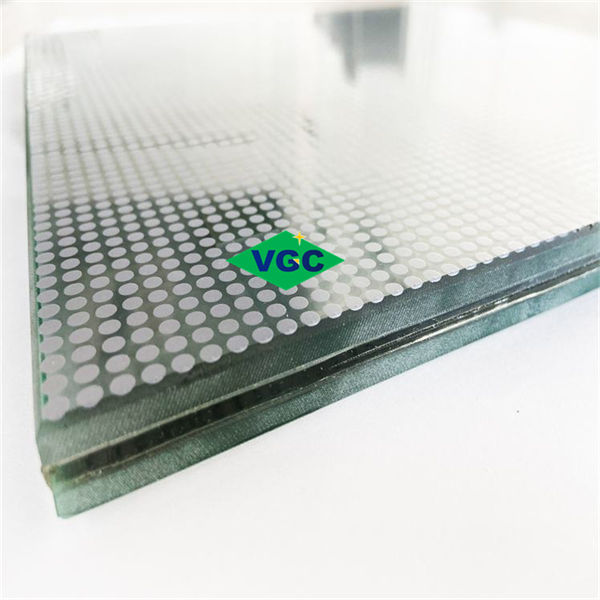

Screened Laminated Glass

Specification

| Product | Clear Float Glass Laminated Glass |

| Types | Clear curved tempered laminated glass; color curved tempered laminated glass ;reflective curved tempered laminated glass; curved tempered laminated patterned glass; curved tempered laminated glass mirror; |

| PVB Colors : | Clear;milky white ;bronze;gray;red;orange ;green,etc. |

| PVB Film Thickness | 0.38mm ;0.76mm ; 1.14mm ; 1.52mm ;1.9mm etc |

| Thickness | 2+0 .38PVB+2mm 3+0 .38PVB+3mm 4+0 .38PVB+4mm 5+0 .38PVB+5mm 6+0.76PVB+6mm 8+1 .52PVB+8mm 10+1 .52PVB+10mm etc |

| Normal Sizes | 1830*2440MM,2140*3300MM,2440*3660MM,1650*2250MM,1000*2000MM,1200*1000MM,ETC |

| Processing | Cut to size ;Edge working ;drilling holes ;making notches;tempering.etc. |

| Packing: | Sea worthy plywood end cap ,with film inter layer |

Architectural Clear Float Laminated Glass VS Tempered Glass

🔹 1. Structure & Manufacturing

Laminated Glass (Clear Float Laminated):

Made by bonding two or more layers of float glass with a PVB/EVA/SGP interlayer under heat and pressure.

Stays intact when broken – fragments adhere to the interlayer.

Tempered Glass (Toughened):

Single sheet of float glass heated to ~650°C then rapidly cooled.

Breaks into small blunt particles when shattered.

🔹 2. Safety Performance

Laminated Glass:

Even if broken, pieces stick to interlayer → prevents injury & maintains barrier.

Resistant to penetration (burglary, forced entry).

Preferred for overhead glazing, skylights, railings.

Tempered Glass:

Stronger impact resistance (4–5x float glass).

Breaks into small cubes – safer than annealed but offers no barrier after breakage.

🔹 3. Strength & Durability

Laminated Glass:

Slightly weaker than tempered in direct impact resistance.

Better long-term durability, especially against UV (with quality interlayer).

Tempered Glass:

Very high strength against impact, wind pressure, and thermal stress.

Vulnerable to spontaneous breakage (e.g., nickel sulfide inclusion).

🔹 4. UV, Sound & Energy Control

Laminated Glass:

Blocks >99% UV rays → protects interiors from fading.

Provides excellent sound insulation due to interlayer.

Can integrate tinted or Low-E coatings.

Tempered Glass:

No inherent UV or sound insulation (unless laminated afterwards).

Why Choose Us?

- Strict Quality&Detail control are the life of the company.

- Provide overall solution.Establish real trust-worthy partnership.

- Clients cooperated together, we can ensure no loss happened.

- Factory competitive prices and best services.

- Factory Monthly output can reach to 30000sqm.

- Established a strict quality management system.

- Professional R&D Team, can customized for clients.

VIRTUE GLASS has always put product quality in the first place as product quality is the life of an enterprise. We try to implement the sense of quality to the heart of every employee,into the production of each link and details, strive for excellence. We take customer’s satisfaction as the main criterion for the assessment of all the production activities, customer demand is always our pursuit. Clear Float Glass Laminated Glass