Buy Tint Laminated Glass from China manufacturer and supplier. Looking for high-quality Tint Laminated Glass products for your home or office?

Check out the options available at VIRTUE GLASS TECH and find the perfect fit for your needs! VGC is a leading Decorative Patterned Laminated Glass manufacturer and supplier. Our products are of the highest quality and offer superior safety and security. Tint Laminated Glass is the perfect solution for safety and security. Explore our range of Tint Laminated Glass products and get a free quote today from Virtue Glass Company.

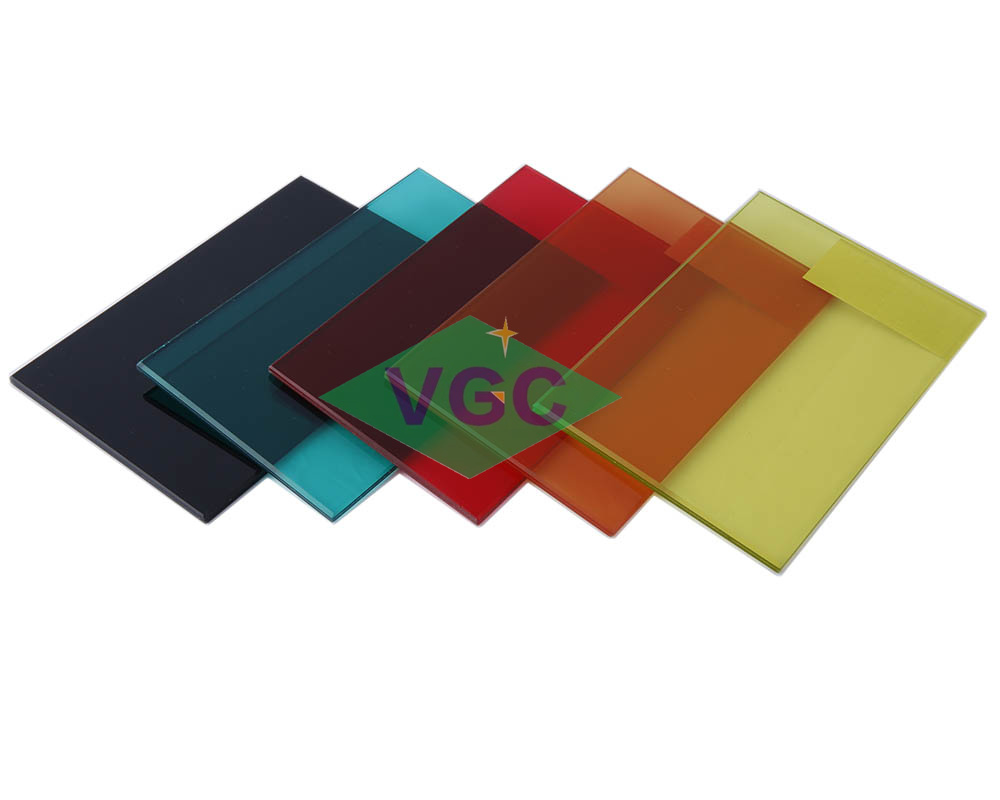

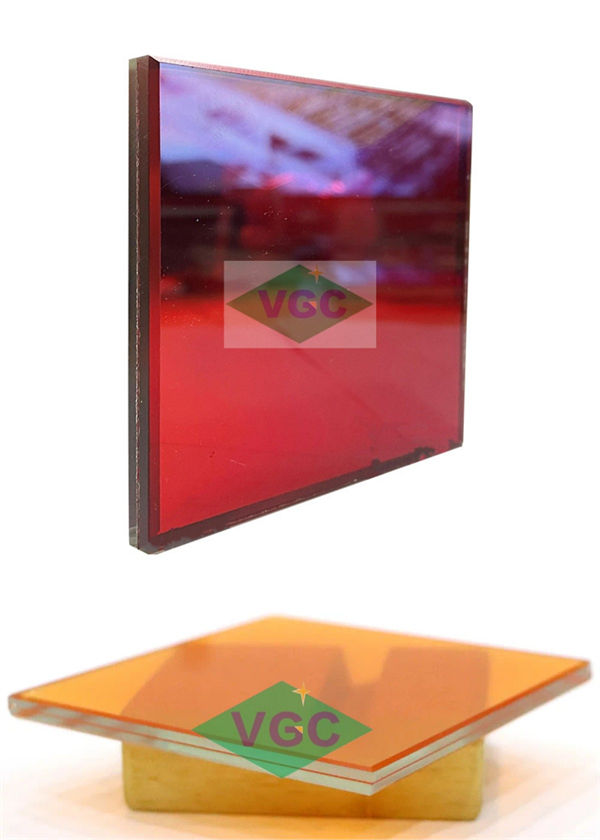

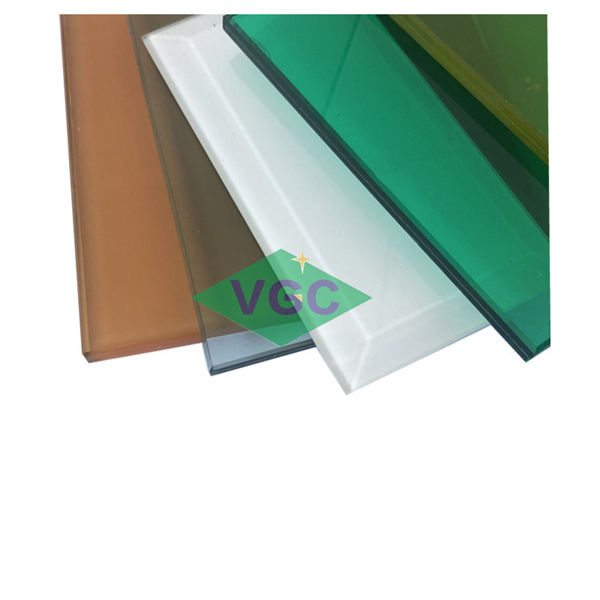

Tint Laminated Glass is produced by laminating one or more layers of organic resin inter-layer between two or more pieces of glass at high temperature and pressure. According to different types of inter-layer, laminated glass can be made into products of different characteristics. Its application should be correctly selected based on the requirements.

Tint-Laminated-Glass

Colored Laminated Glass

Red-Orange-Glass

Tint-Laminated-Glass

Advantages of Tint Laminated Glass

- Safety: Tint Laminated Glass is a type of safety glass, which means that it is designed to SIZE LAMINATED GLASS minimize the risk of injury in the event of an impact. If Tint Laminated Glass is broken, the inter layer material holds the glass fragments together, reducing the risk of injury from flying shards.

- Custom: Because of its strength and durability, Tint Laminated Glass is commonly used in applications where security is a concern.

- Sound reduction: The interlayer material in laminated glass helps to absorb sound waves, making it an effective solution for reducing noise pollution in areas with high levels of noise.

- UV protection: The interlayer material in laminated glass can block up to 99% of harmful UV rays, which can help protect furniture, carpets, and other items in your home or office from fading over time.

- Design flexibility: Tint Laminated Glass is available in a variety of colors, patterns, and thicknesses, allowing designers to create unique and custom solutions for their projects.

Applications of Tint Laminated Glass

Some common design applications include cabinet glass inserts, doors, door inserts, shower enclosures, railings and partitions, glass furniture, privacy windows, accent windows, and more. Pattern glass can be fabricated into various forms of safety glass such as insulated glass units, tempered glass, and laminated glass.

Specification of Tint Laminated Glass

| Product | Tint Laminated Glass |

| Types | Clear Float Laminated Glass, Tempered Laminated Glass, Curved Laminated Glass, Insulated laminated glass,laminated mirror, Pattern Glass laminated |

| PVB Colors : | Clear;milky white ;bronze;gray;red;orange ;green,etc. |

| PVB Film Thickness | 0.38mm ;0.76mm ; 1.14mm ; 1.52mm ;1.9mm etc |

| Thickness | 2+0 .38PVB+2mm 3+0 .38PVB+3mm 4+0 .38PVB+4mm 5+0 .38PVB+5mm 6+0.76PVB+6mm 8+1 .52PVB+8mm 10+1 .52PVB+10mm etc |

| Normal Sizes | 1830*2440MM,2140*3300MM,2440*3660MM,1650*2250MM,1000*2000MM,1200*1000MM,ETC |

| Processing | Cut to size ;Edge working ;drilling holes ;making notches;tempering.etc. |

| Packing: | Sea worthy plywood end cap ,with film inter layer |

Tint Laminated Glass Vs. Tempered Glass

- Laminated Glass and tempered glass, both qualify as types of safety glazing.

- If Broken, tempered glass shatters in small pieces that are less likely to cause injury or damage, the hardness is 5times than normal glass.

- When Laminated Glass is damaged due to external force, the glass fragments will not be detached and maintain the integrity. It also avoid being penetrated. It can be processed into bullet-proof glass or high-strength explosion-proof glass through specific combinations.

- For strength and breakage-resistance, Tint Laminated Glass often is the first consideration.

- For Decoration effect,both Tempered and Tint Laminated Glass can be made colorful.

- Usually, the Laminated Glass and tempered glass can be combined as curved tempered laminated glass,which is very safety for architectural use.

Quality Control of Tint Laminated Glass

- The staff of VIRTUE GLASS are well trained, paying high attention to each procedure each piece of Decorative Patterned Laminated Glass with our increasing efforts.

- Every process in production has quality control, Accurate size and meet the Laminated Glass standards, glass particle size were promise. Using professional testing tools, which were certified by certification authority. The test data of each order is recorded.

- Incoming Quality Control—In Process Quality Control Section—Process Quality Control—Final Quality Control–Out-going Quality Control.

- Our productions are well feedback by domestic and overseas markets. Especially in Europe, America, South America and Middle East markets.

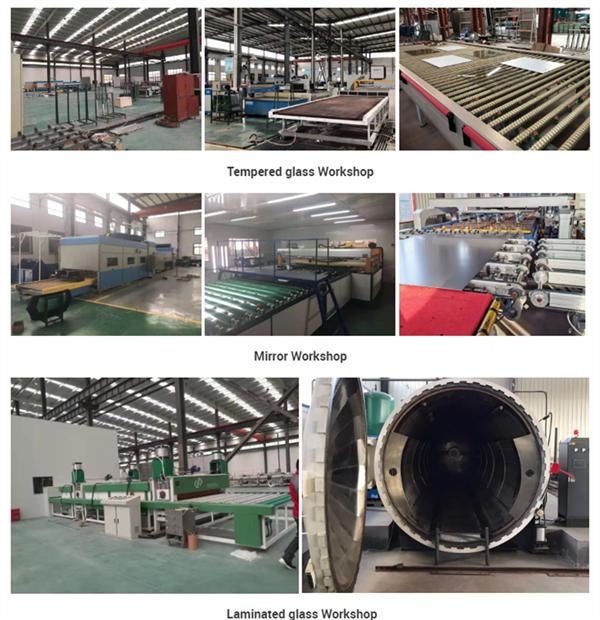

Why Choose Us?

- Strict Quality&Detail control are the life of the company.

- Provide overall solution.Establish real trust-worthy partnership.

- Clients cooperated together, we can ensure no loss happened.

- Factory competitive prices and best services.

- Factory Monthly output can reach to 30000sqm.

- Established a strict quality management system.

- Professional R&D Team, can customized for clients.

VIRTUE GLASS has always put product quality in the first place as product quality is the life of an enterprise. We try to implement the sense of quality to the heart of every employee,into the production of each link and details, strive for excellence. We take customer’s satisfaction as the main criterion for the assessment of all the production activities, customer demand is always our pursuit.