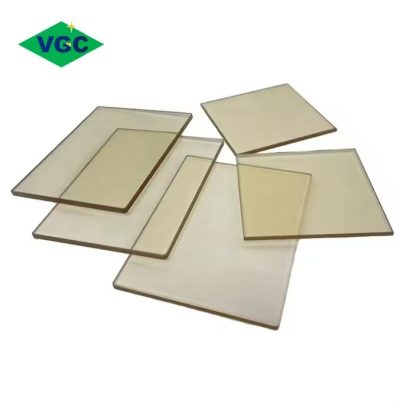

High-Temperature Transparent Ceramic Glass Panels – Professional Manufacturer

Welcome to VIRTUE GLASS TECH, a leading manufacturer of high-performance Transparent ceramic glass. Our specialized glass-ceramic material is engineered to withstand extreme temperatures up to 870°C and resist severe thermal shock, making it the ideal and safe choice for fireplaces, stoves, cooktops, and industrial applications.

Transparent Ceramic Glass Manufacturer

What is Transparent Ceramic Glass?

Transparent ceramic glass, also known as transparent glass-ceramic, is a advanced material created through a controlled crystallization process. This gives it extraordinary thermal stability and a very low coefficient of thermal expansion. Unlike ordinary glass, it barely expands or contracts when heated, allowing it to resist thermal shocks of up to 875°C without cracking. This unique property ensures safety, durability, and perfect optical clarity for viewing flames.

Key Properties & Advantages

Extreme Heat Resistance: Our ceramic glass is rated for continuous use at temperatures up to 870°C, far exceeding the limits of tempered or borosilicate glass.

Superior Thermal Shock Resistance: It can withstand rapid temperature changes of up to 875°C, ensuring reliability in the most demanding conditions, such as direct flame contact.

Excellent Mechanical Strength: This material stands up to everyday wear and tear, offering high resistance to scratches and impacts.

High Efficiency: Panels, such as our 4mm thick cooktop glass, transmit heat efficiently with virtually no loss.

Perfect Clarity: Enjoy an unobstructed view of fireplace flames or industrial processes safely.

Fireplace Ceramic Glass

Primary Applications

Fireplace & Stove Doors: The essential safety component for wood, gas, pellet, and ethanol units.

Glass Ceramic Cooktops: The core material for smooth-top ranges, known for efficient heat transfer.

Industrial Viewing Windows: Used in ovens, furnaces, and high-temperature equipment for process monitoring.

Specialty Lighting & High-Temperature Covers.

Why Choose Us as Your Manufacturer?

Direct OEM Manufacturer: We control quality and cost, offering competitive pricing and OEM services.

Full Customization: We specialize in custom-cutting panels to your exact size, shape, and specifications.

Fast Lead Times: We understand urgency. Typical production time is just 3-7 days after deposit.

Global Shipping: We securely package products in carton boxes or wooden crates for safe worldwide delivery.

Request a Free Quote for Your Project

Have specific requirements? Contact our technical experts today with your specifications for a prompt and precise quotation.

Payment Terms: 30% deposit with the balance paid before shipment.