Buy Low-E Coated Glass From VGC China – Get A Free Quote

What is Low-E Coated Glass?

Low-E Coated Glass is a type of energy-efficient glass that is coated with a thin, transparent layer of metal or metallic oxide. The coating reflects infrared radiation and blocks heat transfer, which helps to keep indoor spaces cooler in the summer and warmer in the winter.

Low-E Coated Glass works by selectively transmitting and reflecting different wavelengths of light. The coating is designed to allow visible light to pass through while reflecting infrared radiation. This means that Low-E glass can reduce the amount of heat that enters or escapes a building through windows, which can help to lower energy costs and improve indoor comfort.

There are two types of Low-E Coated Glass: passive and solar control. Passive Low-E glass is designed to provide insulation, while solar control Low-E glass is designed to reduce solar heat gain. Both types of Low-E glass can be used in a variety of building applications, including windows, doors, and skylights.

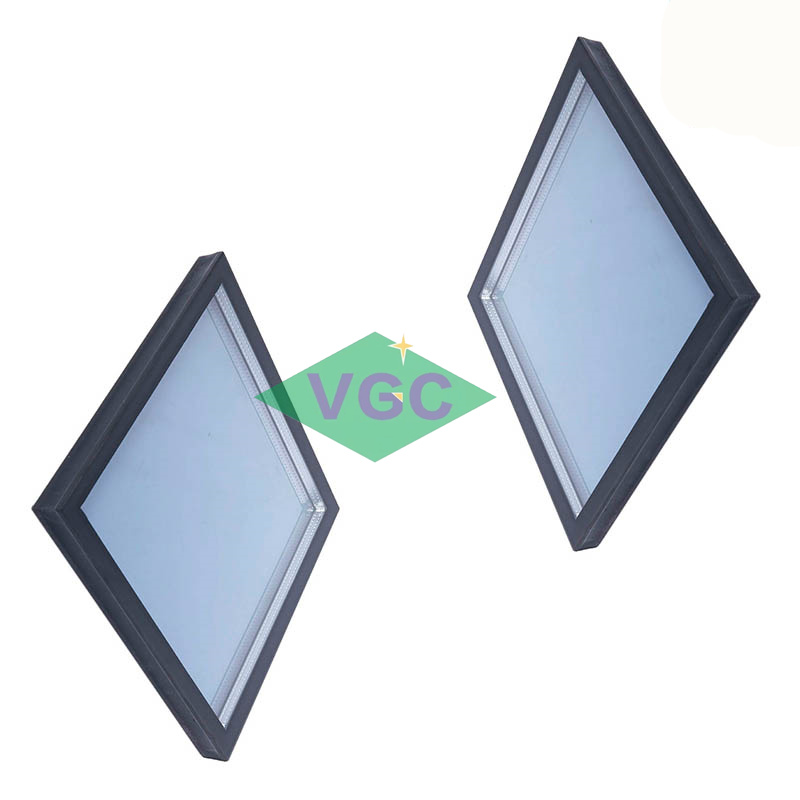

Low-E Coatings Glass

Energy-Efficient Glass

Insulating Glass

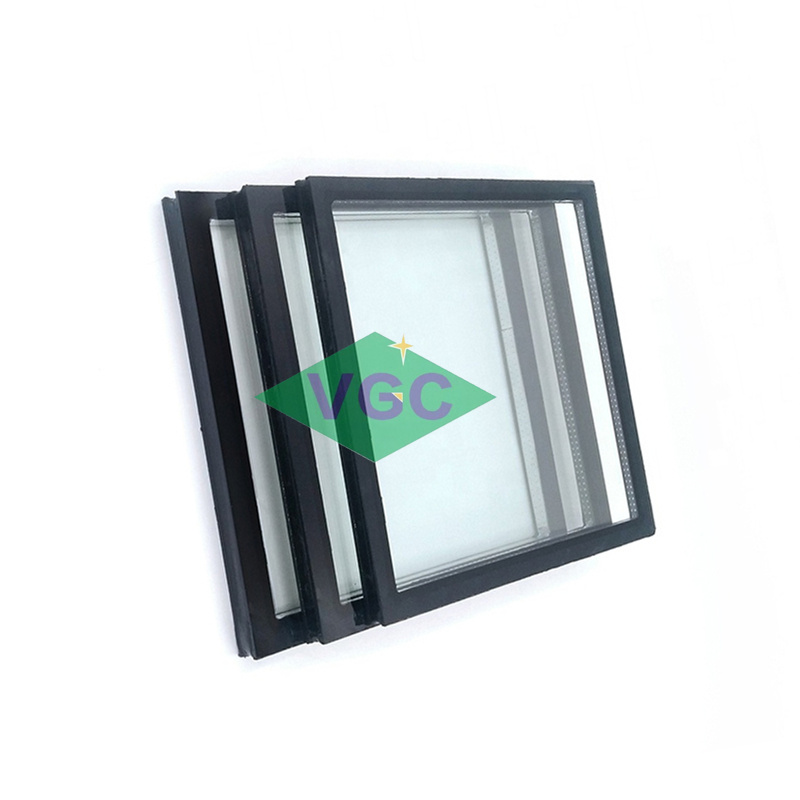

Specificaion of Low-E Coated Glass

| Product | Low-E Coated Glass |

| Types | Passive Control |

| Solar Control | |

| Thickness | 3mm 4mm 5mm 6mm 8mm 10mm 12mm 15mm 19mm etc. |

| Max. Thickness | 57mm |

| Max. Size | 3000mm × 6000mm |

| Min. Size | 100*100mm |

| Edges | Simple grinding edges, polished edges, customized edges |

| Spacer width | 6mm, 9mm, 12mm, 15mm and 16mm |

| Application | Glass Windows,Glass Doors,Glass Curtain Walls, Furniture Glass, Inner and outer Glass Decoration. |

The Advantages of Low-E Coated Glass?

There are several advantages to using Low-E Coated Glass in building design:

- Energy Efficiency: Low-E Coatings Glass can significantly reduce the amount of energy needed to heat or cool a building by minimizing the amount of heat transfer through windows. This can help to reduce energy bills and lower a building’s carbon footprint.

- Comfort: By reducing the amount of heat that enters or escapes a building through windows, Low-E Coatings Glass can help to maintain a more comfortable indoor environment. This can lead to increased productivity and overall well-being.

- UV Protection: Low-E Glass coatings can block up to 99% of harmful UV radiation, which can help to protect furniture, flooring, and artwork from fading and sun damage.

- Versatility: Low-E Coatings Glass can be used in a variety of building applications, including windows, doors, and skylights. It is available in different colors and levels of performance to meet the specific needs of different building designs.

- Cost-Effective: While Low-E Coatings Glass may have a slightly higher initial cost compared to standard glass, its energy-saving benefits can help to offset this cost over time through lower energy bills.

- Low-E Coatings Glass can help homeowners save money on energy costs by reducing heat loss in the winter and heat gain in the summer. It also protects furniture from fading by blocking UV rays, improves indoor comfort, reduces noise, and has a positive impact on the environment.

Overall, Low-E Coatings Glass is an effective way to improve the energy efficiency, comfort, and value of a building while also providing protection against UV radiation.

Low-E Coated Glass vs Normal Glass

Low-E Coatings Glass is a type of glass that has a special coating applied to its surface to reduce the amount of heat transfer through the glass. This coating reflects heat back into a room or building, making it more energy-efficient.

Normal glass, on the other hand, is not coated and allows a significant amount of heat to pass through it. This can result in energy loss and higher heating and cooling costs.

Low-E Coatings Glass can be more expensive than normal glass, but its energy-saving properties can provide long-term savings on energy bills. It can also help to reduce the amount of ultraviolet (UV) light that enters a building, which can help to prevent fading of furniture, carpets, and other interior items.

Low-E Coatings Glass is better than regular glass for energy efficiency and overall performance. Regular glass allows more heat to pass through, resulting in higher energy costs, while low-e glass reflects heat back to its source, reducing the amount of heat entering or escaping a building. Low-e glass also improves comfort and blocks UV rays, even though it may cost more upfront.

Overall, if you’re looking to make your home or building more energy-efficient and reduce your energy costs, Low-E Coatings Glass is a good choice. However, if cost is a major concern, normal glass may be a more affordable option.

Where We Can Use Low-E Coated Glass?

Low-E Coatings Glass can be used in a variety of building applications, including:

- Windows: Low-E Coatings Glass is commonly used in residential and commercial windows to improve energy efficiency and reduce heat gain or loss.

- Doors: Low-E Coatings Glass can be used in exterior and interior doors to provide insulation and UV protection.

- Skylights: Low-E Coatings Glass can be used in skylights to allow natural light into a building while minimizing heat gain.

- Curtain Walls: Low-E Coatings Glass can be used in curtain walls, which are non-structural exterior cladding systems that are typically used in commercial buildings.

- Greenhouses: Low-E Coatings Glass can be used in greenhouses to control temperature and light transmission.

- Automotive Glass: Some cars use Low-E Coatings Glass in their windows to improve fuel efficiency and reduce heat gain.

- Overall, Low-E Coatings Glass is a versatile and effective solution for improving energy efficiency, reducing heat gain or loss, and providing UV protection in a variety of building applications.

Application

How To Choose The Right Low-E Coated Glass For Your Project

- Choosing the right Low-E Coatings Glass for your project depends on several factors, including the climate, building orientation, and desired performance. Here are some tips for selecting the right low-e glass:

- Determine the climate zone: Low-E Coatings Glass coatings are designed to perform differently in different climates. Select a low-e glass coating that is optimized for the climate zone in which your project is located.

- Consider building orientation: Buildings facing different directions may have different energy needs. For example, buildings facing north may require more insulation than buildings facing south. Choose a low-e glass coating that is optimized for the building orientation.

- Identify the desired performance: Low-e glass coatings can vary in terms of their visible light transmission, solar heat gain coefficient, and U-value. Consider your project’s performance needs in terms of natural light, heat control, and insulation.

- Consult with a professional: Work with a professional glass supplier or architect to determine the best low-e glass solution for your project.

- By considering these factors, you can select the right low-e glass coating for your project, optimizing energy performance and comfort.

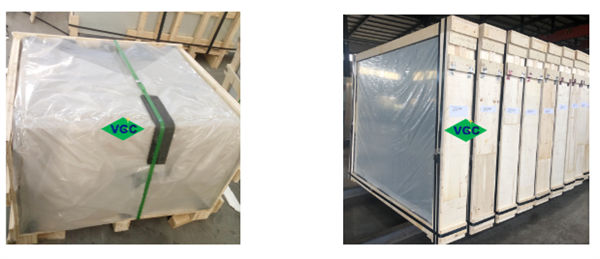

Safety Packaging

Contact Us For Exact Good Prices Low-E Coatings Glass

Email: sales03.virtueglass@aliyun.com

Mob: 86-18561983517

Wechat: AugustVGC2005

VIRTUE GLASS has always put product quality in the first place as product quality is the life of an enterprise. We try to implement the sense of quality to the heart of every employee,into the production of each link and details, strive for excellence. We take customer’s satisfaction as the main criterion for the assessment of all the production activities, customer demand is always our pursuit.