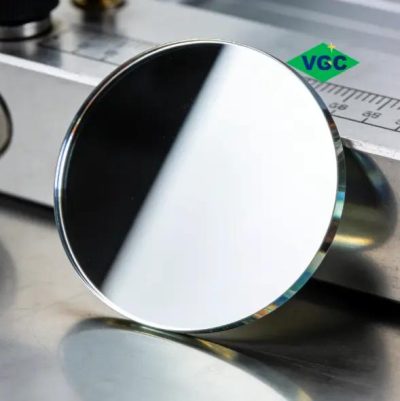

VGC Front Surface Mirror (with coating on the front side) is engineered for superior optical performance and durability, making it a trusted choice for industrial, scientific, and professional imaging applications. Leveraging advanced magnetron sputtering technology under high vacuum conditions, we deposit an aluminum film with an interference-enhancing coating, ensuring exceptional reflectivity across a wide wavelength range. Unlike traditional rear-coated mirrors, the front-side coating eliminates ghosting and image distortion, delivering clear, accurate reflections for critical applications.

Main Advantages of Front Surface Mirror

-

Exceptional Reflectivity: Boasts high reflectivity (up to 96.10%) across 400-600nm wavelengths, meeting strict performance requirements at both 6° and 45° light incidence angles.

-

Precision Manufacturing: Produced via high-vacuum magnetron sputtering, ensuring uniform coating adhesion and consistent optical performance across the entire mirror surface.

-

Superior Durability: Rigorously tested for abrasion resistance, adhesion, humidity resistance, and chemical stability, ensuring long-term reliability in harsh industrial environments.

-

Standard & Customizable Sizes: Available in standard dimensions with tight tolerances, supporting custom specifications to match diverse project needs.

Front Surface Mirror

high reflectivity mirror

Key Specifications

|

Parameter

|

Details

|

Reflectivity

|

|---|---|---|

|

Product Type

|

Front Surface Mirror

(Coating on Front Side)

|

|

|

Coating Technology

|

Interference-enhancing coating, deposited

by magnetron sputtering under high vacuum

|

|

|

Dimensions

|

Thickness: 1.1mm/1.5mm/2.0mm/2.5mm/3.0mm/

4.0mm/5.0mm/6.0mm/8.0mm Sizes: 1830*1220mm,1830*2440mm,2140*3300mm, Any customized sizes. |

400nm: >92% (Measured: 93.65%)

450nm: >93% (Measured: 96.10%)

550nm: >94% (Measured: 94.08%)

600nm: >90% (Measured: 90.59%)(Applicable for both 6° and 45° light incidence angles)

|

Applications of Front Surface Mirror

-

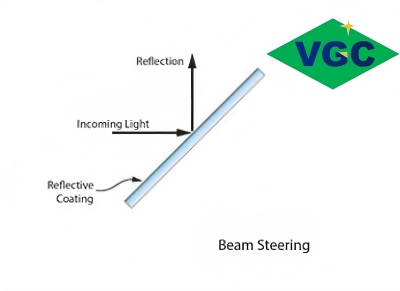

Industrial Imaging & Machine Vision: Ideal for machine vision systems, automated inspection lines, and industrial cameras, providing distortion-free reflections for precise object detection and measurement.

-

Scientific Instruments: Widely used in scientific research equipment such as microscopes, telescopes, spectrometers, and interferometers, ensuring high-precision optical performance for accurate data collection.

-

Laser Systems: Suitable for laser processing equipment (laser cutting, engraving), laser alignment devices, and optical communication systems, due to its high reflectivity and stable performance under laser irradiation.

-

Medical Equipment: Applied in medical imaging devices (endoscopes, ultrasound machines), surgical microscopes, and diagnostic instruments, where clear, accurate reflections are critical for medical procedures and diagnosis.

-

Aerospace & Defense: Used in aerospace optical systems, flight simulators, and defense surveillance equipment, meeting the strict environmental and performance requirements of these high-end fields.

-

Display & Projection Systems: Utilized in projection televisions, head-up displays (HUDs), and virtual reality (VR) devices, eliminating ghosting to enhance the viewing experience.

instrument use front mirror

mirror with front aluminum coating

95% reflectivity front surface mirror