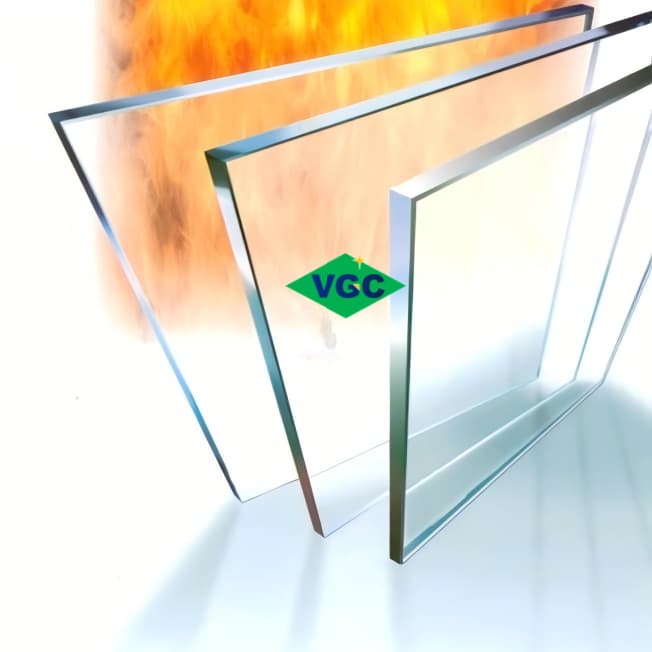

VGC supply Customized High Borosilicate Float Glass . At present, VGC Special Glass, integrates production, processing, sales, and service, with a product portfolio covering borosilicate 3.3 float glass, borosilicate 4.0 fireproof glass, borosilicate 2.6 float glass. Its sales network has now expanded to many countries and regions worldwide.

High Borosilicate Float Glass is a special type of glass made by the float process, in which molten glass is floated on a bed of molten metal (usually tin) to form a flat, uniform sheet.

High Borosilicate Float Glass

Main Characteristics

- Super fireproof performance – up to 3 hours

- Ultra-lightweight – over 8% lighter compared to normal glass

- High whiteness and excellent light transmittance

- Very high mechanical strength

- Superior water and chemical resistance

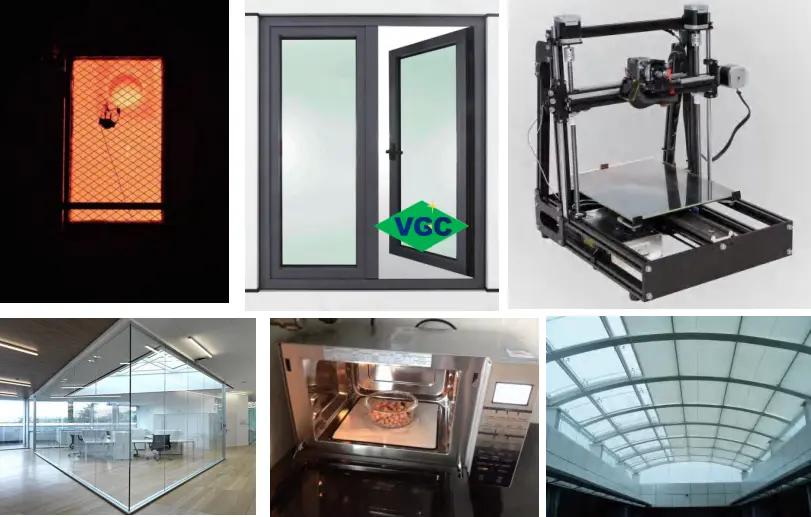

Applications of High Borosilicate Float Glass

Smoke Curtains – Used as smoke barriers in public buildings, shopping malls, airports, and underground facilities to control smoke spread during fire incidents.

Fireproof Partitions – Ideal for creating transparent fire-resistant walls in offices, hospitals, schools, and commercial centers.

Glass Curtain Walls – Suitable for large-scale building facades requiring both fire resistance and high light transmittance.

Fireproof Windows – Applied in residential and commercial buildings to provide fire-rated protection while maintaining natural lighting.

Interior Fireproof Separations – Used in corridors, stairwells, escape routes, and compartment areas to ensure safe evacuation.

Why High Borosilicate Float Glass?

Compared with standard float glass, high borosilicate glass offers superior thermal resistance, chemical stability, and mechanical strength. Its unique composition allows it to withstand extreme temperature changes, making it an ideal material for fire safety applications.

Key Features & Advantages:

- Excellent Fire Resistance – Designed to delay the spread of fire and provide critical evacuation time.

- High Thermal Stability – Can endure rapid temperature changes without breaking.

- Exceptional Clarity – Ultra-clear surface with high light transmission.

- Durability – Long service life with outstanding chemical and impact resistance.