In the dynamic world of optical components,High Reflectivity Front Surface Mirror (FSMs) stand as indispensable pillars for high-precision applications—from cutting-edge industrial machine vision to groundbreaking scientific research and life-saving medical equipment. Unlike ordinary rear-coated mirrors, High Reflectivity Front Surface Mirror boast a reflective coating directly applied to the front side of the glass substrate, wiping out annoying image distortion and ghosting that can compromise critical operations. This article takes an in-depth dive into the core advantages, technical brilliance, and wide-ranging applications of front surface mirrors, with a special focus on the premium offerings from VGC Glass—your trusted partner for top-tier optical solutions. Whether you’re a B2B buyer seeking reliable components or an industry professional striving for operational excellence, these insights will guide you to make informed, value-driven decisions.

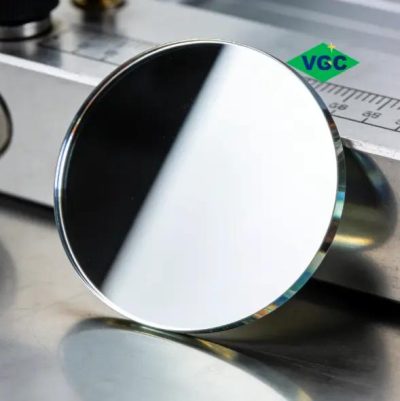

95% high reflectivity front surface mirror

What Is a High Reflectivity Front Surface Mirror? Core Technical Characteristics

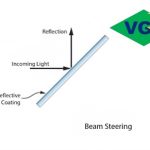

High Reflectivity Front Surface Mirror is also known as a first-surface mirror, is an optical mirror where the reflective coating (typically aluminum or silver) is deposited on the front face of the glass substrate. This design differs fundamentally from rear-surface mirrors (common household mirrors), which have the coating on the back side of the glass.

The secret behind the exceptional performance of high-quality High Reflectivity Front Surface Mirror lies in their state-of-the-art coating technology—and VGC Glass leads the way in this field. We adopt magnetron sputtering under high vacuum to deposit the reflective layer, typically an aluminum film enhanced with an interference coating. This sophisticated process, mastered by VGC Glass’s team of experts, guarantees uniform coating thickness, rock-solid adhesion, and outstanding reflectivity across a broad wavelength spectrum (400-600nm), perfectly catering to the rigorous demands of most industrial applications.

At VGC Glass, we hold ourselves to the highest standards, and our industrial-grade front surface mirrors come with impressive technical specifications that set them apart:

-

Reflectivity: 92%-96% across 400-600nm wavelengths (critical for low-light or high-precision optical systems)

-

Substrate thickness: 4mm-10mm (6mm is standard for industrial use, with tight tolerance of ±0.2mm)

-

Dimensional accuracy: Length/width tolerances as low as ±2.0mm, ensuring compatibility with standard optical setups

-

Coating durability: Passes rigorous tests for abrasion, humidity, salt spray, and chemical resistance (compliant with DIN ISO and EN ISO standards)

- high reflectivity Front Surface Mirror

- high reflectivity mirror

- mirror with front aluminum coating

- instrument use front mirror

High Reflectivity Front Surface Mirror vs. Rear Surface Mirror: Key Advantages

The primary advantage of High Reflectivity Front Surface Mirror—especially those crafted by VGC Glass—stems from their innovative front-side coating design, which solves the frustrating limitations of rear-surface mirrors. Below is a detailed comparison chart highlighting the core differences, helping you understand why VGC Glass’s High Reflectivity Front Surface Mirror are the ultimate choice for high-precision applications where quality cannot be compromised.

|

Comparison Dimension

|

Front Surface Mirror

|

Rear Surface Mirror

|

|---|---|---|

|

Coating Position

|

Front side of glass substrate

|

Back side of glass substrate

|

|

Image Quality

|

No ghosting or distortion; clear,

accurate reflections

|

Ghosting (double images) due to light

refraction through glass; potential distortion

|

|

Reflectivity

|

High (92%-96%) across broad wavelengths

|

Lower (typically 85%-90%) due to

light loss through glass substrate

|

|

Application Suitability

|

High-precision industrial, scientific,

medical, and laser applications

|

Household, decorative, and low-precision

applications

|

|

Durability

|

Superior (coating protected by specialized treatments;

passes salt spray, humidity, and chemical tests)

|

Lower (coating prone to peeling or corrosion

without proper backing protection)

|

Core Advantages of VGC Glass’s Industrial-Grade High Reflectivity Front Surface Mirror

Beyond outperforming rear-surface mirrors, front surface mirrors offer a range of advantages tailored to industrial and professional needs:

1. Exceptional Optical Clarity & Precision

The front-side coating eliminates the “ghost image” effect common in rear-surface mirrors. This is critical for applications where image accuracy is non-negotiable—such as machine vision inspection, where even minor distortion can lead to faulty product detection, or medical imaging, where clear reflections support accurate diagnosis.

2. High Reflectivity Across Critical Wavelengths

Thanks to the interference-enhancing coating deposited via magnetron sputtering, front surface mirrors maintain high reflectivity (up to 96.10% at 450nm) across the visible light spectrum (400-600nm). This makes them ideal for low-light environments (e.g., scientific spectrometers) and laser systems, where consistent reflectivity ensures stable performance.

3. Superior Durability for Harsh Environments

At VGC Glass, we understand that industrial environments can be harsh—that’s why our High Reflectivity Front Surface Mirror undergo rigorous, industry-leading quality testing to ensure unwavering durability, no matter the conditions. Our mirrors excel in every challenge:

-

Abrasion resistance: Withstands 200+ strokes with a soft cloth (fully compliant with DIN ISO 9211-4-01-01)

-

Corrosion resistance: Passes 48-hour salt spray tests (DIN EN ISO 9227 NSS) and 48-hour humidity tests (DIN EN ISO 6270-2 CH), resisting rust and degradation

-

Chemical resistance: Stands strong after 24 hours of immersion in salt solutions, isopropyl alcohol, and acetone at room temperature

-

Temperature stability: Endures 7 days of high-temperature storage at 100°C and repeated climatic cycles (4h/80°C, 4h/-30°C), maintaining performance in extreme heat and cold

4. Customizability for Diverse Applications

We believe in tailor-made solutions to meet your unique needs. We offer front surface mirrors in a wide range of customizable sizes (such as length 1800±2.0mm, width 1350±4.0mm or 1340±2.0mm) and thicknesses (6.0±0.2mm as standard). This remarkable flexibility allows us to craft mirrors that fit seamlessly into your specific equipment—whether it’s a compact scientific instrument or a large-scale industrial inspection line—ensuring perfect integration and optimal performance.

Key Applications of Front Surface Mirrors Across Industries

The unbeatable combination of optical precision, rugged durability, and high reflectivity makes VGC Glass’s front surface mirrors the preferred choice across multiple high-growth industries. Below are the most prominent application areas, where VGC Glass FSMs deliver exceptional value and drive success:

1. Industrial Imaging & Machine Vision

In the fast-paced world of automated manufacturing and quality control, machine vision systems rely on crystal-clear, distortion-free images to keep operations running smoothly. VGC Glass’s front surface mirrors are the backbone of these systems, capturing every detail with pinpoint accuracy. Key applications include: Automated inspection lines for electronics (e.g., detecting tiny defects in circuit boards, ensuring product perfection)Robotic vision guidance systems in automotive assembly (enabling precise, efficient production)Packaging inspection (guaranteeing seal integrity and label accuracy, protecting your brand reputation) With VGC Glass FSMs eliminating ghosting entirely, your vision system receives accurate, reliable data for real-time decision-making—minimizing errors and maximizing productivity.

2. Scientific Research & Instruments

Scientific breakthroughs depend on ultra-precise optical components, and VGC Glass’s front surface mirrors have become a trusted staple in laboratories and research facilities worldwide. They shine in: Microscopes (compound, stereo, and electron microscopes) for stunningly clear specimen imaging, unlocking the secrets of the microcosmTelescopes and astronomical observatories (capturing faint celestial light with exceptional reflectivity, expanding our understanding of the universe)Spectrometers and interferometers (measuring light wavelengths and wavefronts with unmatched accuracy, ensuring reliable, reproducible scientific data) When you choose VGC Glass, you’re equipping your research team with tools that inspire discovery and drive innovation.

3. Laser Systems & Optical Communication

Laser technology demands mirrors that can withstand high-power irradiation while maintaining consistent reflectivity—and VGC Glass’s front surface mirrors rise to the challenge brilliantly. They’re essential in: Laser cutting, engraving, and marking equipment (directing laser beams with pinpoint precision, delivering flawless results every time)Laser alignment systems (ensuring accurate beam positioning in industrial and medical lasers, critical for safety and performance)Optical communication networks (reflecting and routing light signals with minimal loss, keeping data flowing smoothly) The magnetron-sputtered coating exclusive to VGC Glass’s FSMs ensures unwavering stability under laser exposure, preventing coating degradation and extending the lifespan of your equipment.

4. Medical Equipment & Diagnostics

In healthcare, precision can mean the difference between life and death—and VGC Glass’s front surface mirrors play a critical role in life-saving diagnostic and surgical equipment. They’re trusted in: Endoscopes (providing crystal-clear views of internal body structures during minimally invasive procedures, reducing patient trauma and improving outcomes)Surgical microscopes (delivering ultra-high-precision imaging for delicate surgeries, empowering surgeons to perform with confidence)Ultrasound and imaging systems (enhancing image clarity for accurate diagnosis, ensuring early detection and effective treatment) VGC Glass’s FSMs meet the strict biocompatibility and durability standards of sterile medical environments, making them a reliable choice for healthcare professionals worldwide.

5. Aerospace & Defense

Aerospace and defense applications demand components that can thrive in the harshest, most extreme environmental conditions—and VGC Glass’s front surface mirrors are built to excel. They’re deployed in: Aerospace optical systems (satellite imaging, flight navigation displays) where reliability is non-negotiableFlight simulators (providing realistic visual feedback for pilot training, preparing them for real-world scenarios)Defense surveillance equipment (night vision goggles, target acquisition systems) where clarity and durability can impact mission success VGC Glass’s FSMs meet the stringent temperature, vibration, and corrosion resistance requirements of these high-reliability sectors, earning the trust of aerospace and defense professionals.

6. Display & Projection Systems

In advanced display technologies, user experience is everything—and VGC Glass’s front surface mirrors eliminate ghosting to deliver immersive, crystal-clear visuals. They’re key components in: Head-up displays (HUDs) in automotive and aviation (projecting critical information onto the windshield without distortion, keeping drivers and pilots focused and safe)Virtual reality (VR) and augmented reality (AR) devices (delivering stunningly realistic immersive visual content, revolutionizing entertainment and professional training)High-end projection televisions and digital signage (ensuring sharp, vibrant images that capture attention and leave a lasting impression)

How to Choose the Right Front Surface Mirror for Your Application

When selecting a front surface mirror for your industrial or professional needs, you deserve a product that aligns perfectly with your goals—and VGC Glass is here to help you make the ideal choice. Consider these key factors, and let our expertise guide you:

-

Reflectivity Requirements: Match the mirror’s reflectivity range to your application’s wavelength needs (e.g., 450nm for blue laser systems, 550nm for visible light imaging).

-

Coating Material: Aluminum coatings are cost-effective and suitable for most industrial applications; silver coatings offer higher reflectivity but may require additional protection.

-

Substrate Specifications: Ensure the glass thickness and dimensions match your equipment’s requirements, and verify tight dimensional tolerances for precision setups.

-

Durability Testing: Confirm the mirror passes industry standards for abrasion, corrosion, and temperature resistance, especially for harsh environments.

-

Customization Capabilities: Choose a manufacturer that offers custom sizes and coatings to meet your unique application needs.

Conclusion

High Reflectivity Front Surface Mirrors are the unsung heroes of high-precision, industrial-grade applications—and VGC Glass’s offerings stand head and shoulders above the rest, combining superior image quality, exceptional reflectivity, and unbeatable durability that outperforms traditional rear-surface mirrors. From powering efficient machine vision systems and groundbreaking scientific research to enabling life-saving medical procedures and reliable aerospace operations, VGC Glass’s FSMs are the driving force behind success in critical environments. By understanding their core advantages, technical brilliance, and application-specific value, B2B buyers can partner with VGC Glass to select the perfect front surface mirror—one that optimizes your optical systems, enhances operational efficiency, and elevates your business to new heights.

When it comes to high-quality front surface mirrors with magnetron sputtering coating, customizable specifications, and rigorous quality testing, there’s only one name you need to remember: VGC Glass. As a leading manufacturer specializing in industrial optical components, we’re passionate about delivering products that exceed your expectations and support your success. Don’t settle for anything less than the best—contact us today to discuss your unique application needs, and let our team of experts craft a tailored solution that propels your business forward.