Tempered glass, as a widely used safety glass material in architectural curtain walls, windows, window walls, and other key applications, plays an irreplaceable role in ensuring structural safety and user security. However, the potential risk of spontaneous breakage of tempered glass has long been a concern in the industry. Heat soak treatment (HST), a crucial quality control process for tempered glass and heat-treated laminated glass, has been universally recognized as the most effective and efficient method to minimize this risk. As a professional glass deep processing and export enterprise, VIRTUE GLASS TECH QINGDAO CO.,LTD (VGC Glass) strictly implements heat soak treatment that complies with international standards for all relevant glass products, providing reliable quality assurance for global customers.

VGC Heat Soak Treatment for Tempered Glass

1. The Root Cause of Spontaneous Breakage of Tempered Glass

The main cause of spontaneous breakage of tempered glass lies in the nickel sulfide (NiS) inclusions present in the glass raw materials. During the glass melting process, nickel and sulfur impurities may form nickel sulfide crystals. These crystals exist in two stable forms at different temperatures: the high-temperature α-phase and the low-temperature β-phase. When the glass is tempered at a high temperature (above 600°C) and rapidly cooled, the nickel sulfide in the glass is trapped in the high-temperature α-phase state. In the subsequent service process of the glass, as the temperature changes and time elapses, the α-phase nickel sulfide will gradually transform into the β-phase. This phase transformation is accompanied by a volume expansion of about 4-5%, which generates enormous internal stress in the tempered glass. When this stress exceeds the strength limit of the glass, the glass will break suddenly without any external force, i.e., spontaneous breakage.

This kind of spontaneous breakage is highly unpredictable and can occur months or even years after the glass is installed, posing significant safety hazards to people and property, especially in high-rise buildings, public facilities, and other scenarios.

2. The Core Role of Heat Soak Treatment

Heat soak treatment is a post-tempering process designed to accelerate the phase transformation of nickel sulfide inclusions, thereby identifying and eliminating potentially defective glass before it leaves the factory. The process simulates the long-term service environment of the glass in a short period, making the glass with nickel sulfide inclusions break in a controlled factory environment, rather than in the actual application site.

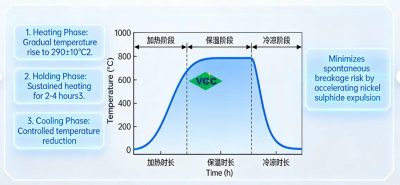

Specifically, the heat soak process cycle consists of three key phases: heating phase, holding phase, and cooling phase. In the heating phase, the tempered glass is uniformly heated to a specific temperature (usually around 290°C ± 10°C). In the holding phase, the glass is maintained at this temperature for a certain period (generally 2-4 hours) to fully promote the phase transformation of nickel sulfide. In the cooling phase, the glass is slowly and uniformly cooled to room temperature to avoid new thermal stress. Through this process, the vast majority of tempered glass with nickel sulfide inclusions that may cause spontaneous breakage can be eliminated, greatly reducing the risk of subsequent safety accidents.

It should be emphasized that heat soak treatment is not only applicable to single-piece tempered glass but also to heat-treated laminated glass (tempered laminated glass). For laminated glass, the heat soak process can also effectively detect potential quality problems of the tempered glass substrate, ensuring the overall safety and reliability of the laminated glass product.

3. International Standards and Industry Requirements for Heat Soak Treatment

With the widespread recognition of the importance of heat soak treatment, many international organizations and countries have formulated relevant standards to regulate the heat soak process of tempered glass. Among them, BS EN 14179-1:2005 is one of the most authoritative and widely adopted standards in the global glass industry. This standard specifies the technical requirements, test methods, and quality control criteria for the heat soak treatment of thermally toughened soda-lime-silica safety glass.

In many key application fields, especially in architectural curtain walls, windows, and window wall projects, heat soak treatment has become a mandatory quality control measure. It is widely recognized in the industry that all tempered glass panes used in these important scenarios should be subjected to heat soak treatment that conforms to BS EN 14179-1:2005 or other equivalent international standards (such as ASTM standards in North America). This not only ensures the safety of the building structure but also reflects the professional responsibility and quality pursuit of glass manufacturers and construction units.

4. VGC Glass’s Strict Heat Soak Treatment Process

As a professional glass manufacturer focusing on export to Europe, North America, South America, and other affluent regions, VGC Glass has always adhered to the principle of “quality first, safety first” and incorporated heat soak treatment into the core quality control system of tempered glass and heat-treated laminated glass products.

VGC Glass’s heat soak treatment process strictly complies with the requirements of BS EN 14179-1:2005 international standard. We have equipped advanced fully automatic heat soak furnaces, which can realize precise control of temperature and time during the heating, holding, and cooling phases. The entire process is monitored by a professional intelligent system to ensure that each piece of glass is uniformly heated and cooled, avoiding local overheating or excessive temperature difference.

Before the heat soak treatment, VGC Glass’s quality inspection team will conduct a strict pre-inspection of the tempered glass, including the inspection of glass thickness, flatness, edge quality, and surface defects, to ensure that only qualified semi-finished products enter the heat soak process. During the heat soak process, professional technicians conduct real-time monitoring and record relevant process parameters (such as heating rate, holding temperature, holding time, cooling rate, etc.) in detail to form a complete quality traceability system. After the heat soak treatment, the glass is subjected to a second strict inspection to confirm that there are no defects such as cracks or breakages, and then it is sent to the next production process.

In addition to strict compliance with international standards, VGC Glass can also adjust the heat soak process parameters according to the specific requirements of customers and the characteristics of different application scenarios to provide personalized and professional heat soak treatment solutions. Our heat soak-treated tempered glass and heat-treated laminated glass products have passed CE and other relevant international certifications, fully meeting the market access requirements of Europe, North America, and other regions.

process of Glass Heat Soak Treatment

5. Conclusion

Heat soak treatment is an indispensable key process to ensure the safety and reliability of tempered glass and heat-treated laminated glass. It is the most effective means to eliminate the risk of spontaneous breakage of tempered glass caused by nickel sulfide inclusions. Complying with international standards and implementing strict heat soak treatment is not only the basic requirement of the glass industry but also the responsibility of glass manufacturers to customers and society.

VGC Glass has always been committed to providing high-quality, safe, and reliable glass products for global customers. With our professional heat soak treatment process, strict quality control system, and perfect after-sales service, we have won the trust and recognition of customers in Europe, North America, and other regions. Whether it is tempered glass for architectural curtain walls, heat-treated laminated glass for high-end buildings, or other customized glass products, VGC Glass can provide you with comprehensive quality assurance and professional solutions.

For more information about VGC Glass’s heat soak treatment process and glass products, please visit our official website: www.virtueglassgroup.com