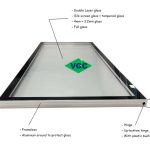

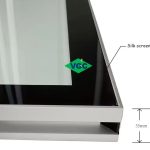

In the competitive refrigeration industry, the performance of freezer glass directly impacts energy consumption, product preservation, and user experience. VGC Tempered Insulated Freezer Glass, engineered with advanced LOW-E glass as materials and precision manufacturing, stands out as a premium solution for commercial and industrial refrigeration equipment. Combining exceptional thermal insulation, superior mechanical strength, and long-term reliability, this glass product is tailored to meet the rigorous demands of freezers, display coolers, and low-temperature storage units.

Tempered Insulated Freezer Glass

Advantages: Energy Efficiency & Premium Quality

1. Outstanding Energy-Saving Performance

VGC Tempered Insulated Freezer Glass adopts a high-performance double-glazed or triple-glazed insulated structure, filled with dry inert gas (argon or krypton) between the glass layers. This specialized design effectively blocks heat transfer, minimizing the thermal bridge effect and reducing the load on refrigeration compressors. Compared with LOW-E energy saving glass, our insulated freezer glass can reduce energy consumption by 30%-45%, significantly lowering the long-term operating costs for end-users. The low-emissivity (Low-E) coating option further enhances thermal insulation by reflecting infrared radiation, ensuring stable low-temperature environments inside the freezer without excessive energy input.

2. Superior Mechanical Strength & Safety

The base glass of VGC products is processed through full-tempering technology, which increases its surface strength by 3-5 times compared to annealed glass. It can withstand impact from heavy objects (conforming to ISO 12543-1 standard) and resist thermal shock caused by sudden temperature changes (from -40℃ to 80℃ without cracking). In case of breakage, the tempered glass shatters into small, blunt-edged fragments, eliminating the risk of sharp cuts and ensuring user safety. Additionally, the glass is equipped with a durable sealant system that maintains structural integrity even in extreme low-temperature environments, preventing air leakage and condensation.

3. Excellent Durability & Longevity

VGC Tempered Insulated Freezer Glass is designed for long-term use in harsh refrigeration conditions. The high-quality sealant (polyurethane or butyl rubber) used in the insulated structure has excellent resistance to aging, corrosion, and low temperatures, ensuring no seal failure for more than 15 years. The glass surface is also optional with anti-fog, anti-scratch, or anti-UV coatings, which not only maintain clear visibility for display freezers but also prevent surface damage and discoloration caused by long-term use and environmental factors.

- Insulated door glass

Product Range: Types, Thickness, Sizes & Technical Parameters

1. Product Types

-

Tempered Double Insulated Freezer Glass (2 layers)

-

Tempered Triple Insulated Freezer Glass (3 layers)

-

Low-E Tempered Insulated Freezer Glass (with Low-E coating)

-

Anti-Fog Tempered Insulated Freezer Glass (with anti-fog coating)

-

Anti-Scratch Tempered Insulated Freezer Glass (with hard coating)

2. Customization Range

Size customization: Maximum size up to 2440mm × 3660mm; Minimum size 300mm × 300mm. Custom shapes are available, including rectangle, square, and rounded corner, tailored to customer’s equipment design.

Main sizes:1600*520mm,1580*300mm,1950*400mm etc.

3. Key Technical Parameters

|

Parameter Item

|

Standard Value

|

Test Standard

|

|---|---|---|

|

Thermal conductivity (U-value)

|

0.5-1.2 W/(m²·K) (depending

on layer and gas filling)

|

ISO 10077-1

|

|

Impact resistance

|

No breakage when impacted by

1kg steel ball from 1.5m height

|

ISO 12543-1

|

|

Temperature resistance range

|

-60℃ to 120℃

|

GB/T 9963-2016

|

|

Sealing performance

|

No air leakage or condensation

after 1000 hours of low-temperature

testing

|

ISO 12543-2

|

|

Bending strength

|

≥ 150 MPa

|

ISO 1288-1

|

|

Anti-fog performance

|

No fogging at -25℃ to 25℃

temperature difference

|

Customized industrial standard

|

Application Scenarios

VGC Tempered Insulated Freezer Glass is widely used in various refrigeration equipment, including:

-

Commercial display freezers (supermarkets, convenience stores, shopping malls)

-

Industrial low-temperature storage freezers (food processing plants, pharmaceutical warehouses)

-

Household and commercial refrigerators (upright freezers, chest freezers)

-

Refrigerated display cabinets (bakery, dairy, seafood display)

-

Special refrigeration equipment (laboratory low-temperature cabinets, medical refrigerators)

Why Choose VGC Tempered Insulated Freezer Glass?

VGC adheres to strict quality control standards throughout the production process, from raw material selection to finished product inspection. Our products are certified by international authorities such as ISO, CE, and SGS, ensuring compliance with global market requirements. We also offer customized solutions according to customers’ specific needs, including personalized sizes, coatings, and insulation performance. With professional R&D teams and efficient after-sales service, VGC is committed to providing reliable, high-performance freezer glass products that help customers improve product competitiveness and reduce operating costs.

For more information about VGC Tempered Insulated Freezer Glass, please contact our sales team. We look forward to establishing long-term cooperative relationships with you!