Low Reflection Laminated Glass For Museum Display Cases

Ultra Clear Glass AR Glass Substrate

Core Performance Advantages: Tailored for Museum Display Requirements

-

Ultra-High Light Transmittance & Ultra-Low Reflectivity: Visible light transmittance ≥ 97.3% and visible light reflectance ≤ 1%, minimizing light reflection and maximizing the clarity of cultural relics. Visitors can view artifacts without glare interference, while the glass itself becomes “invisible” to highlight the relics.

-

Superior UV Protection: Blocks 99.5% of UV light (wavelength 320–380 nm), effectively preventing UV radiation from fading, discoloring, or deteriorating precious cultural relics such as paintings, textiles, and paper artifacts. This provides long-term protection for cultural heritage.

-

Exceptional Color Reproduction: Color rendering index ≥ 99.5%, haze ≤ 0.1%, and yellow index ≤ 0.2%, ensuring no color distortion. The glass faithfully reproduces the original color and texture of cultural relics, allowing visitors to perceive the true appearance of historical artifacts.

-

Reliable Safety Performance: Complies with GB15763.3-2009 “Building Safety Glass Part 3: Laminated Glass”. Passes ball drop impact and shotgun bag impact tests—after impact, the glass does not break or produce fragments, and the interlayer is not exposed, avoiding damage to cultural relics from glass shards.

-

Long-Term Durability: Excellent resistance to radiation, heat, and humidity. After radiation resistance testing, the visible light transmittance change rate is less than 1%; no bubbles or defects occur after heat and humidity tests. The glass also has superior acid resistance, alkali resistance, and wear resistance, complying with GB/T 18915.1-2013, ensuring stable performance in long-term museum environments.

VGC Low Reflection Laminated Glass: Rigorous Quality Control Standards

VGC Glass enforces a stringent quality control (QC) system throughout the entire production cycle of Low Reflection Laminated Glass, guaranteeing that every product meets the stringent requirements of museum display applications. All our products are accompanied by scanned third-party test reports certified by CMA or CNAS, offering authoritative quality assurance to our global clients:

– Appearance Quality: Free from internal bubbles, visible impurities, or surface blemishes. Under normal natural light, no visible scratches are detectable when viewed from 600mm away for 10 seconds. Cracks, breakages, delamination, wrinkles, and streaks are strictly forbidden; point or linear defects within the visible area fully comply with relevant standard specifications.

– Curvature Control: The maximum arch curvature is ≤ 0.03%, and the maximum waveform curvature is ≤ 0.02%, ensuring exceptional flatness and structural stability of the glass.

– Interlayer Quality: Adopts PVB film with a thickness of no less than 0.76mm. For glass with a height exceeding 2700mm, SGP anti-bending film is mandatory. This enhances the glass’s structural strength, bending resistance, and optical transparency simultaneously.

Precise Specifications for Museum Display Cases

VGC Low Reflection Laminated Glass adheres to strict dimensional and flatness requirements to ensure perfect integration with museum display cases and optimal viewing effects:

– Flatness Requirements: Surface flatness error within 1mm; allowable deviation in flatness ±1mm/m; allowable deviation in edge curvature ±1mm/m.

– Squareness & Dimensional Accuracy: Diagonal error per meter does not exceed 1.5mm. Corner joints are assembled according to actual needs to ensure aesthetic splicing.

– Edge & Corner Processing: Exposed edges are finely polished; exposed corners have safe chamfers to prevent scratches and ensure visitor safety.

– Splicing Requirements: Whenever possible, the display case glass is designed as a whole piece. For necessary splicing, the largest possible glass size is used. Fixed or movable splicing seams are sealed, and seam processing minimizes visual perception of the joints.

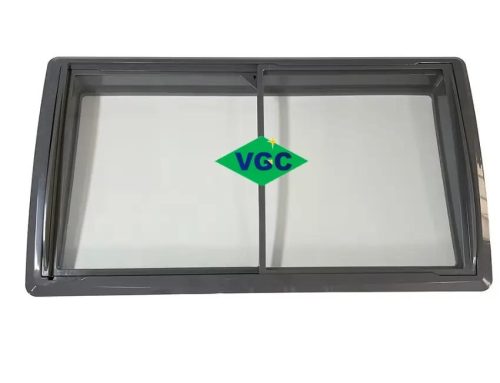

Low reflection Museum Display glass

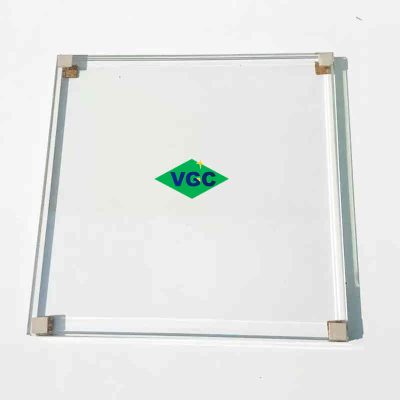

Low reflection Museum glass

Flexible Specifications & Processing Options

To meet the diverse needs of different museum display projects, VGC Low Reflection Laminated Glass offers flexible customization and comprehensive processing support:

– Thickness Customization: The thickness of the low-reflection laminated glass is customized according to the specific requirements of the display case (e.g., size, load-bearing, and safety requirements), ensuring optimal performance and safety.

– Size Customization: Supports customized sizes to match various display case designs, from small showcase glass to large-scale exhibition wall glass.

– Processing Options: Professional processing services including precision cutting, fine edge grinding, safe chamfering, and customized splicing, fully adapting to the unique design needs of museum display cases.

Why Choose VGC Low Reflection Laminated Glass for Museums?

As a professional glass manufacturer focusing on global exports to Europe, North America, South America, and other affluent regions, VGC Glass has rich experience in providing high-end glass solutions for cultural and artistic institutions. Choosing VGC Low Reflection Laminated Glass means:

– Professional Customization Capability: Tailored solutions according to the unique needs of museum display cases, ensuring perfect matching with exhibition designs.

– Authoritative Quality Assurance: Strict compliance with international and national standards, with complete third-party testing reports (CMA/CNAS certified) to ensure product reliability.

– Factory-Direct Cost-Effectiveness: Direct supply from the factory eliminates intermediate links, reducing procurement costs while ensuring product quality.

– One-Stop Service: Comprehensive services covering demand consultation, sample customization, mass production, and logistics, providing professional one-on-one follow-up throughout the process.

VGC Low Reflection Laminated Glass is committed to protecting cultural heritage and enhancing the viewing experience for visitors. Whether for small-scale cultural relic showcases or large-scale museum exhibition halls, we can provide you with high-quality, safe, and reliable glass solutions. For more details about product specifications, testing reports, or to request a quotation, please visit our official website: www.virtueglassgroup.com or contact our professional team directly.