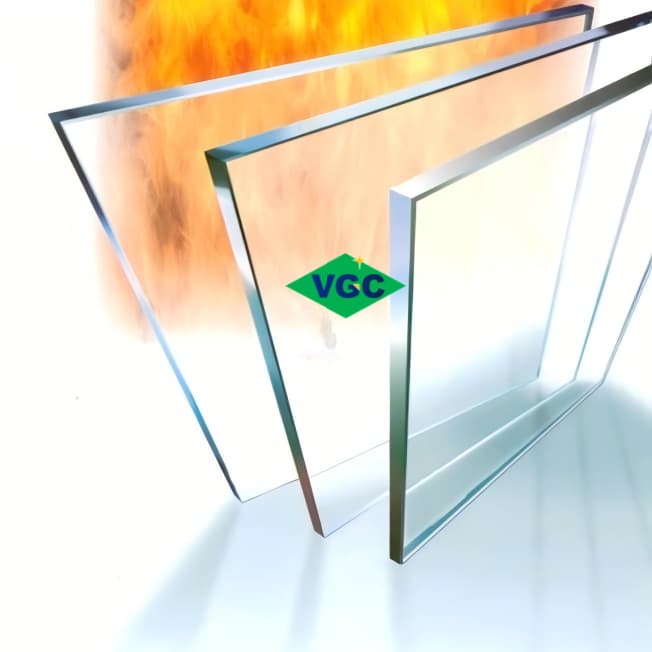

VGC High Safety Fire Proof Borosilicate Glass, a material that is redefining fire-resistant design in modern architecture. In today’s construction industry, safety and aesthetics are no longer separate goals. Among the most innovative solutions is . Architects, developers, and property owners are looking for building materials that deliver fire protection, durability, and visual appeal.

VGC High Borosilicate Float Glass Includes:3.3 and 4.0 Safety Fire Proof Borosilicate Glass

• Super fireproof performance – up to 3 hours

• Ultra-lightweight – over 8% lighter compared to normal glass

• High whiteness and excellent light transmittance

• Very high mechanical strength

• Superior water and chemical resistance

What is High Borosilicate Float Glass?

High borosilicate float glass is manufactured through an advanced float process using borosilicate materials. With a higher content of silica and boron oxide, it offers:

1.Outstanding heat resistance – stability under extreme temperatures

2.Excellent chemical durability – resistant to acids, alkalis, and corrosion

3.Superior optical clarity – smooth surface and high transparency

This makes it an ideal choice for fireproof glass applications, where safety and performance are critical.

High Borosilicate Float Glass

Fireproof Performance

Unlike ordinary tempered glass, which may shatter under sudden heat, High Safety Fire Proof Borosilicate Glass maintains its structure and integrity during fire exposure. Depending on the thickness and processing, it can:

1.Resist high temperatures for up to 120–180 minutes

2.Prevent flames and smoke from spreading between compartments

3.Ensure valuable evacuation time and property protection

This level of safety has made it widely used in projects requiring compliance with EN 13501, ASTM, and other international fire standards.

Key Features & Advantages (Safety Fire Proof Borosilicate Glass)

1-Fire Resistance: Stable performance under high heat, ideal for fire-rated applications

2-High Transparency: Light transmittance up to 90% (depending on thickness)

3-No Spontaneous Breakage: Safer than standard tempered glass

4-Durability: Long service life with excellent weather resistance

5-Versatility: Can be laminated, insulated, or coated to combine fire resistance with other functions (soundproofing, thermal insulation, anti-blast)

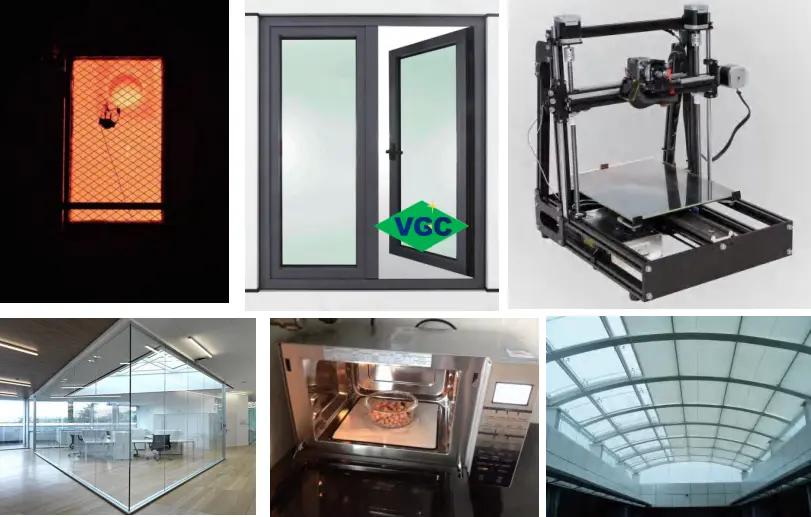

Applications of Fireproof High Borosilicate Float Glass

Smoke Curtains – Used as smoke barriers in public buildings, shopping malls, airports, and underground facilities to control smoke spread during fire incidents.

Fireproof Partitions – Ideal for creating transparent fire-resistant walls in offices, hospitals, schools, and commercial centers.

Glass Curtain Walls – Suitable for large-scale building facades requiring both fire resistance and high light transmittance.

Fireproof Windows – Applied in residential and commercial buildings to provide fire-rated protection while maintaining natural lighting.

Interior Fireproof Separations – Used in corridors, stairwells, escape routes, and compartment areas to ensure safe evacuation.

Market Trend: A Growing Demand for Fire-Safe Glass

As fire safety codes become stricter worldwide, the demand for fire-resistant building materials continues to rise. High Safety Fire Proof Borosilicate Glass not only meets the requirements of fireproof construction but also supports the architectural trend toward open, transparent, and modern spaces.

VGC Fireproof Glass Application